- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Application of Vacuum Freeze Drying Technology in Solid Beverage(一)

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

Application of Vacuum Freeze Drying Technology in Solid Beverage(一)

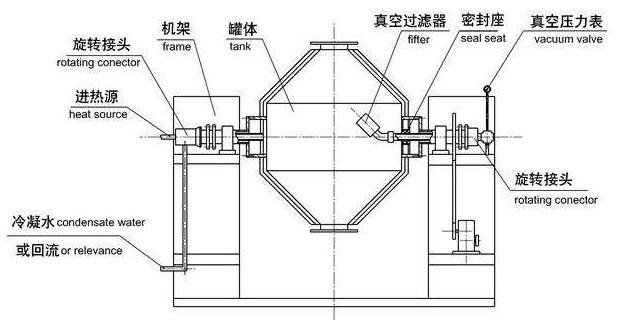

2018-12-27 13:55:36The vacuum freeze-drying technique is a drying technique in which a wet material or a solution is frozen to a solid state at a lower temperature, and then the water therein is directly sublimed into a gaseous state without a liquid state, and finally the material is dehydrated.

At present, vacuum freeze-drying is widely used in the food industry, such as dry coffee, juice, seafood, mushroom slices, ginseng and the like. In recent years, vacuum freeze-drying technology has become one of the main drying methods for preparing solid beverages. It has the advantage of maintaining good physical properties and nutrients, and is one of the main ways to produce high quality fruit and vegetable flour.

1 vacuum freeze drying technology and its impact on food quality

1.1 Influence of vacuum freezing technology on structural characteristics

The effects of different drying methods on the quality of jujube powder were discussed. It was found that the particle size and bulk density of vacuum freeze-dried jujube powder were the smallest. The study found that the sweet potato water under vacuum freeze-drying directly sublimates from the ice crystal state, and can maintain its original shape and form a porous structure. The jujube products prepared by vacuum freeze-drying have larger and more uniform voids and exhibit a better honeycomb structure. Through experimental research, it was found that the surface of the vacuum freeze-dried fish fillet has no cracks, the shape remains intact, the structure of the striated muscle is clearly visible, and the viscoelasticity of the amorphous matrix is reduced.

1.2 The effect of vacuum freezing technology on vitamin C

The pear jujube powder was prepared by different drying methods. It was found that the vacuum freeze-drying treatment can make the vitamin C content of pear jujube powder the highest. The research on the effects of three methods of drying, such as hot air drying, vacuum drying and vacuum freeze drying, on the quality of mountain tablets, found that vacuum freeze-dried yam lost the least vitamin C, and vacuum freeze-drying was the most effective in maintaining vitamin C content in mountain tablets. .

1.3 Influence of vacuum freeze-drying technology on volatile substances

GC-MS was used to analyze the aroma components of chestnuts in five drying modes. A total of 49 substances were detected, of which 28 were vacuum freeze-dried flavors. It was found that a total of 68 volatile flavor components were identified in four drying methods, among which 35 were identified after vacuum freeze-drying, and the relative content of alcohols was the highest.

A comparative study found that there are 20 volatile flavor components in vacuum freeze-dried black soybean kernels, which have a great influence on volatile flavors of alcohols, aldehydes, ketones, sulfur-containing and heterocyclic compounds.

1.4 The effect of vacuum freeze drying technology on color

The study found that the vacuum freeze-dried broccoli color is darker and darker, confirming that vacuum freeze-drying can effectively prevent the decomposition of substances and protect the easily oxidized components. Comparing the effects of different drying methods on the color of tartary buckwheat, it was found that the tartary buckwheat sample of vacuum freeze-drying technology is closest to the color of fresh buckwheat bud, which is related to the lower degree of pigment damage in the process of vacuum freeze-drying of tartary buckwheat. Through experimental research, it was found that the vacuum freeze-dried orange peel had the smallest shrinkage and deformation, the color was the closest to the fresh sample, and the brown peel value was the smallest.

1.5 Influence of vacuum freeze-drying technology on nutrient content

The study found that vacuum freeze-drying had the least effect on the total polyphenol content and antioxidant activity of banana chips. Studies have shown that vacuum freeze-drying can maintain the content of soluble solids better, and the total amount of amino acids in the prepared dragon fruit is larger, and the total amount of 7 essential amino acids is the highest. It was found through experiments that the content of total phenol and anthocyanin in the bayberry powder obtained by vacuum freeze-drying was the highest, and the product had the highest oxidation resistance.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line