- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Palm kernel oil production process

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

Palm kernel oil production process

2019-01-14 13:50:50Palm kernel secondary pressing process

The palm kernel stored in the raw material warehouse is sent to the storage box above the primary press through the conveying device, and the material is buffered and then put into the oil press for pressing, and the pressed cake is collected and lifted and sent to the storage material above the secondary press. The box is buffered for a second press. The oil obtained from the two presses is collected in a crude oil tank and filtered and sent to the wool tank.

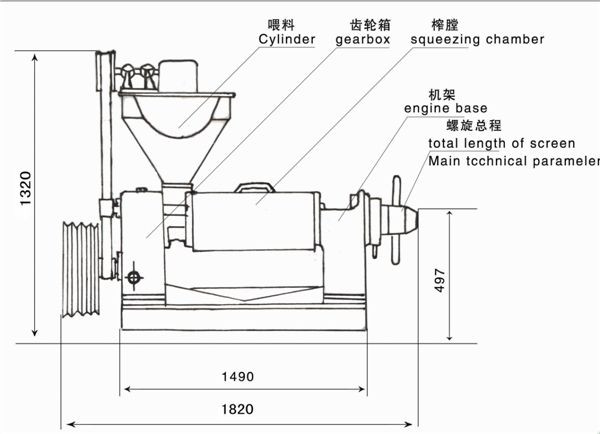

The processing capacity of the oil press used in the microwave drying machinery technology is generally about 15t/d, and the secondary pressing process is used. A factory with a daily processing capacity of 1000t uses about 150 oil presses (including spare presses). Excessive, resulting in a large footprint and maintenance staff and other drawbacks.

The palm kernel stored in the raw material warehouse is transported to the workshop through the scraper. After the metering, the impurities such as large impurities and small impurities are removed by the self-balanced vibrating screen, and then the light impurities are removed by the air sorter to enter the magnetic separator to remove the ferromagnetism. Impurities. The cleaned material is distributed to the first-stage crusher through the scraper for crushing. The first-stage crushed material is directly slid into the secondary crusher through the control valve, and the second-stage crushed material is slipped into the rolling mill for rolling the embryo, after rolling the embryo The material is collected by the scraper and sent to the oil press for oil extraction. The extracted oil enters the Chengyou tank through the oil slag scraper, is coarsely filtered and sent to the oil tank, and then sent to the blade filter through the oil pump for filtration. , get the hair oil. The cake squeezed out by the oil press is collected by the scraper and sent to the leaching workshop.

Due to the small amount of raw materials, palm kernel oil cannot form large-scale production in China, but it has a broad market in Southeast Asia. I hope that the experience of this project will provide a certain reference for opening the palm oil market in Southeast Asia and making China's oil extraction equipment and technology go out.

Throughout the current situation of palm kernel oil extraction, it is still dominated by small oil press processing plants, but most of them are in a state of suspension due to high operating costs. With the rapid development of the palm industry, these small palm kernels are attached to palm oil mills. The oil plant will inevitably be replaced by a large modern oil mill, and the new palm kernel oil production process is also innovating, so it is necessary to explore together with the oil industry colleagues.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line