- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Study on Microwave Drying Process of Seaweed

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

Study on Microwave Drying Process of Seaweed

2019-01-19 09:42:08The purple leafy plant of the genus Amaranthaceae, such as radish and round seaweed, can be made into a traditional Chinese medicine, which has the effects of resolving phlegm and softening, clearing away heat and replenishing water, and nourishing the kidney and nourishing the heart.

The edible protein content of seaweed is generally 24% to 28%, which is much higher than that of ordinary vegetables, and the human body has more amino acids. The constituent amino acids of laver protein, such as alanine, aspartic acid, glutamic acid, glycine, proline, etc., have more neutral and acidic amino acids, which are not characteristic of all terrestrial vegetable plants.

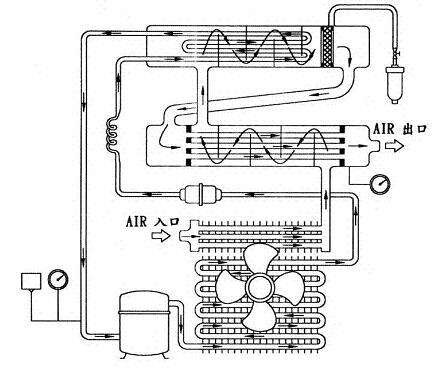

Pharmacological studies have shown that it has enhanced cellular and humoral immune function, slowed heart rate, enhanced myocardial contractility, anticoagulation, hypolipidemic, anti-tumor, anti-aging, anti-radiation, anti-leukocyte count reduction, blood glucose lowering, anti-liver injury And so on. Seaweed is an important cultured red algae along the coast of China. It is not only delicious but also nutritious. China's seaweed resources are abundant and there are many types, and the development of valuable polysaccharides from them has a great future. Microwave food drying and sterilizing machine.

In order to maximize the nutritional value of laver, improve the drying efficiency of laver and avoid waste of resources, it is especially important to study the drying method of laver. At present, the drying method of seaweed has methods such as hot air drying, microwave drying, and vacuum freeze drying. However, there are few reports on the drying of seaweed by microwave drying technology. Therefore, the drying process parameters of seaweed were studied by microwave drying technology. The effects of laver thickness, microwave power and microwave time on the moisture content of seaweed were analyzed. .

Through experimental observation and data analysis, the optimal microwave drying process parameter combination of laver was determined, and the favorable scientific basis for microwave drying technology in the field of agricultural product drying was provided. In the experiment, wet laver was used as raw material, and the extraction conditions for ensuring the quality of the product were obtained by orthogonal test method, which provided a valuable reference for improving the processing technology of laver.

Through the single factor test and orthogonal test of laver, the levels of factors such as microwave power, stack thickness, and microwave time are preferred. The results of L9(34) orthogonal optimization experiments show that the main factors affecting the processing technology of laver are microwave power and microwave time, followed by stacking thickness. The preferred scheme is A3B3C1, that is, the microwave time is 12 min, the stacking thickness is 5 mm, and the microwave power is 300 W. Under this microwave condition, the sensory score of laver was 93.2 and the moisture content was 5.0%.

The microwave freeze-drying technology of seaweed as a product of interdisciplinary development can maintain its color, aroma and moisture content during the processing of seaweed, and has important significance in storage. Microwave freeze-drying technology is easy to control and high in efficiency, and has broad prospects in the food processing industry.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line