- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Application of microwave technology in puffed food processing

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

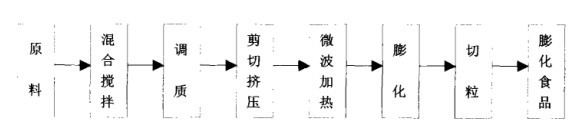

Application of microwave technology in puffed food processing

2018-10-19 14:45:10

As a new heating technology, microwave heating machinery and equipment technology has been widely used in food drying, blanching, thawing, insecticide, sterilization and other fields, and the application of microwave technology in food puffing process is still rare.

The extrusion/ Inflating food processing Line is the use of microwave heating machinery sterilization function.

Because microwave heating is to make the heated object become a heating body, microblogging passes through the food from all directions, heating inside and outside the food at the same time, neither heating medium nor convection, the temperature inside and outside the food rises at the same time, heating speed is fast and uniform, and can better retain the nutrients in the food and the original color of the food. Flavor and flavor are beneficial to improve the quality of expanded granule food.

Therefore, using microwave technology to transform the conventional heating methods (hot water, steam, resistance wire and electrical induction heating method) has important application value.

Advantages of microwave heating

Conventional heating method (hot water, steam, resistance wire and electrical induction heating method) heat source outside, the temperature inside the material rises from the surface to the inside, that is, after the surface heat, mainly rely on heat conduction to the inside, because the medium is poor conductor, so the heat transfer is very slow. Microwave heating is the process of absorbing energy generated by the interaction of microwave energy and target materials.

In this process, the microwave can penetrate into the material without the heat conduction of the object itself to heat. Through the direct interaction of microwave energy with the material, the surface and the interior are heated together, the temperature rises rapidly, the heating time is very short, only a fraction of the time of conventional heating method or One part of the fuselage, and the microwave heating equipment itself does not consume heat, most of the heat energy is applied to the material, thermal efficiency, energy saving.

Sterilization, freshness keeping and high product quality.

Microwave can penetrate into the heated material, so that the surface and internal temperature of the material rise at the same time, so the heating uniform, consistent in the table. Compared with the traditional drying method, it not only has the advantages of high heating efficiency, short heating time and low temperature, but also can better maintain the original material composition, better maintain the original color, aroma, taste and nutrient content in the material, and has a unique germicidal advantage, which is conducive to improving the quality and production of puffed food. Product storage period.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line